Overview

Yatong Pet Flakes Recycling Crushing Washing and Drying Line

This professional-grade pet bottle cleaning production line is designed to efficiently recycle discarded PET plastic bottles. Featuring a powerful crushing mechanism and advanced cleaning system, this production line effectively transforms waste into valuable, high-quality secondary PET materials for reuse. Whether you are looking to reduce your company's environmental impact or seeking economical ways to produce PET products, this pet bottle cleaning production line is the perfect solution. Invest in our product today and join the growing movement towards a more sustainable future.

Product Description

Work Processing:

Bale breaker →Bottle conveyer→ Label separator → Belt conveyer → Crusher → Screw conveyer→ Washing tank → Screw conveyer → Hot washer → (High-speed friction washing machine) → Screw conveyer → Washing tank→ Horizontal washer→Screw conveyer→ Dewatering machine→ Blower drying system → Storage hopper → Finished product packing

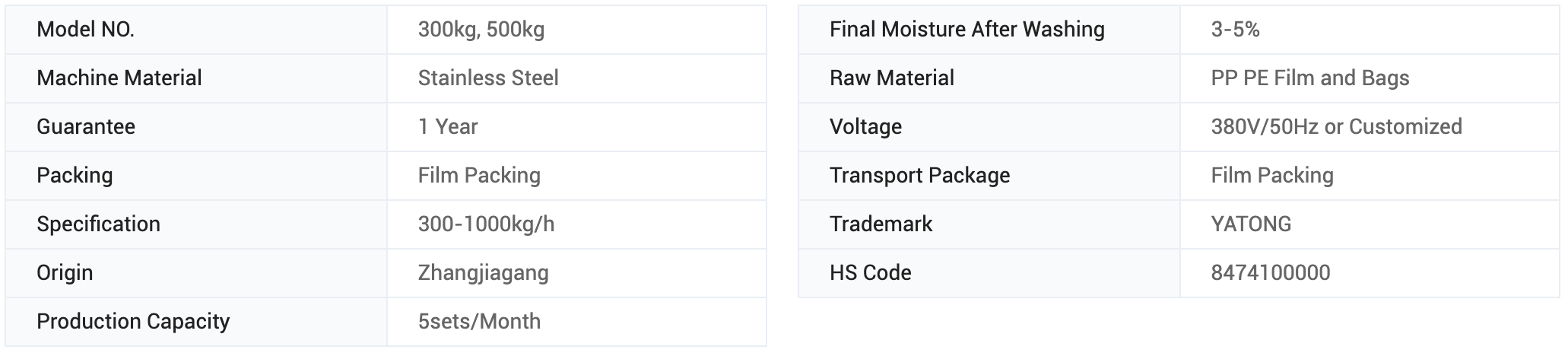

Specifications:

Product capacity | 300kg/h | 500kg/h | 1000kg/h | 2000kg/h |

Workshop(L*W*H) | 40m*7.5m*6m | 42m*10m*6m | 70m*12m*6m | 75m*15m*6m |

Needed worker | 3-4 persons | 5-6persons | 7-8persons | 10-12persons |

Water supply (recycle use) | 2-3ton/h | 7-10ton/h | 10-15ton/h | |

Final product | Moisture: max 3% Bulk density: 0.3G/CM3 Particle size: 10-18mm Metal content: max.20ppm Floatable contamination: less than 200ppm Total impurity: 100-320ppm | |||

REMARK : if the equipment or technological parameters have some change , we shall not make a notice separately .

Features:

1.Plastic recycling washing machine is applied in PET waste bottle or sheet recycling field.

2.Through crushing, washing and drying process, the waste bottle or sheet will become to be bottle flakes. The flakes are widely used in plastic industry, like sheet, and profile production.

3.The clean flakes can be used to produce the polyester staple fiber, PET strap band, granules, PET transparent film and sheets, etc. The top class flakes can be used to blow bottles again.

4. recycling machine can be designed on the basis of how dirty the flakes are, and make sure of the quality of the final products are very clean.

5. recycling machine output we can supply is from 300kg/h to 2000kg/h.

6.We can also produce the plastic pipe extrusion line,plastic profile extrusion line,wood plast composite extruion line,plastic recycling productio line.

Packaging & Shipping

Confirmed all .We will pack the each part as the loading quantity by the shrinking film .the parts all packed by wooden case or boxes .Each step we all done very well to avoid any demage when arrived the destination port .

Our Services

Our principle: only after testing, machine can leave the factory. and only qualified, it can be delivered.

1.We supply one year guarantee for all of our machines.

2.We free supply 1 years normal spare parts for all of our machines.

3.24 hours service.

4.After service is full life of machine.

Company Profile

+86-13812870999

+86-512-58570999

+86-512-585793999